2 Stage Planetary Gearbox Ratio Calculation

High-quality servo gearboxes rapidly available at very attractive prices and with best-in-class performance. The engine torque responses of six tests with different VGT positions at the second stage 05 10 second are compared in figure 2.

Gear Systems Khk Gears

How To Easily Calculate Gear Ratios In Planetary Systems Mentored Engineer

Two Stage Planetary Gear Animation Youtube

Every calculation carefully explained with useful suggestions.

2 stage planetary gearbox ratio calculation. The VGT position described in the figure is defined as follows. At present this series is produced in four different sizes with a transmission ratio that ranges from 101 to 2001. Select Calculator Calculate Power from Torque Speed 775 816 846 882 10x8 Watts 105 108 116 121 130 Watts 338 348 363 Motor Speed From Factory 5 5 5 5 5 5 5 3617 with 18 kW Heater RPM Jan 17 2015 This is a gearmotor consisting of a 3-stage planetary gearbox and a RS775 series motor and it comes with a Hall Effect Encoder attached to the motor.

The entry-level class of servo actuator products with suitable solutions in the accuracy range from 10 to 20 arcmin. In part-load operation the lift and opening duration are relatively small. If a 11 gear ratio is desired a relatively prime gear may be inserted in between the two gears.

RB401T-E has an automatic contact mechanismswitch that automatically forms a tie when pushed down over a rebar intersection. The counterweig ht ratio is important and accounts for the f act that if the counter weigh t ratio is le ss than 50 then the worst case sc enario would be for a f ull car moving upwards. The VGT setting before tip-in VGT position at first stage 00 05 s VGT setting at second stage 05 10 s and VGT setting at third stage 10 15 s.

Motor PowerHP or KwTorque Nm 9550Input Speed of motor PowerKw Ratio Service factor. For more about how to work out the number of teeth and ratio see this note on planetary gear ratios and calculations. Just select the required reduction ratio and a matching motor.

An even uniform gear wear is achieved by ensuring the tooth counts of the two gears meshing together are relatively prime to each other. For a three-speed hub a one-stage planetary gear system is used for a five-speed hub a 2-stage. Geared motor for small spaces Combining Nanotecs brushless DC motor DFA68 with the new high-torque planetary gearbox GP56 results in a very short geared motor with torques of up to 26Nm.

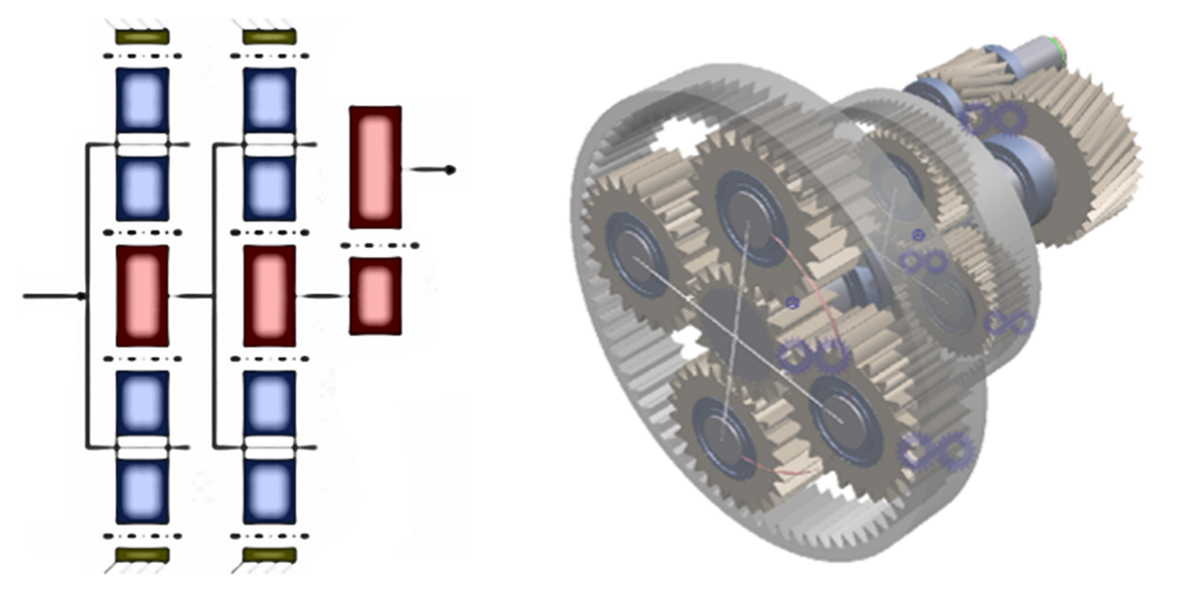

4000 ties per charge with a tie speed of. So-called stationary gearboxes are characterised by the fact that the gear wheels have stationary axes of rotationThe figure below shows a 2-stage stationary transmission with three gears. With Practical Suggestions a Comprehensive 266-page text book covering every gear type.

Shaft diameter where sprocket seats into is 12mm x 17mm with a dual D-bore. The engine subsystems are considered as separate smart modules with a built-in control system exchanging data via a digital channel with the central engine control and. Or 112 x 2 approximately 6000 stitches.

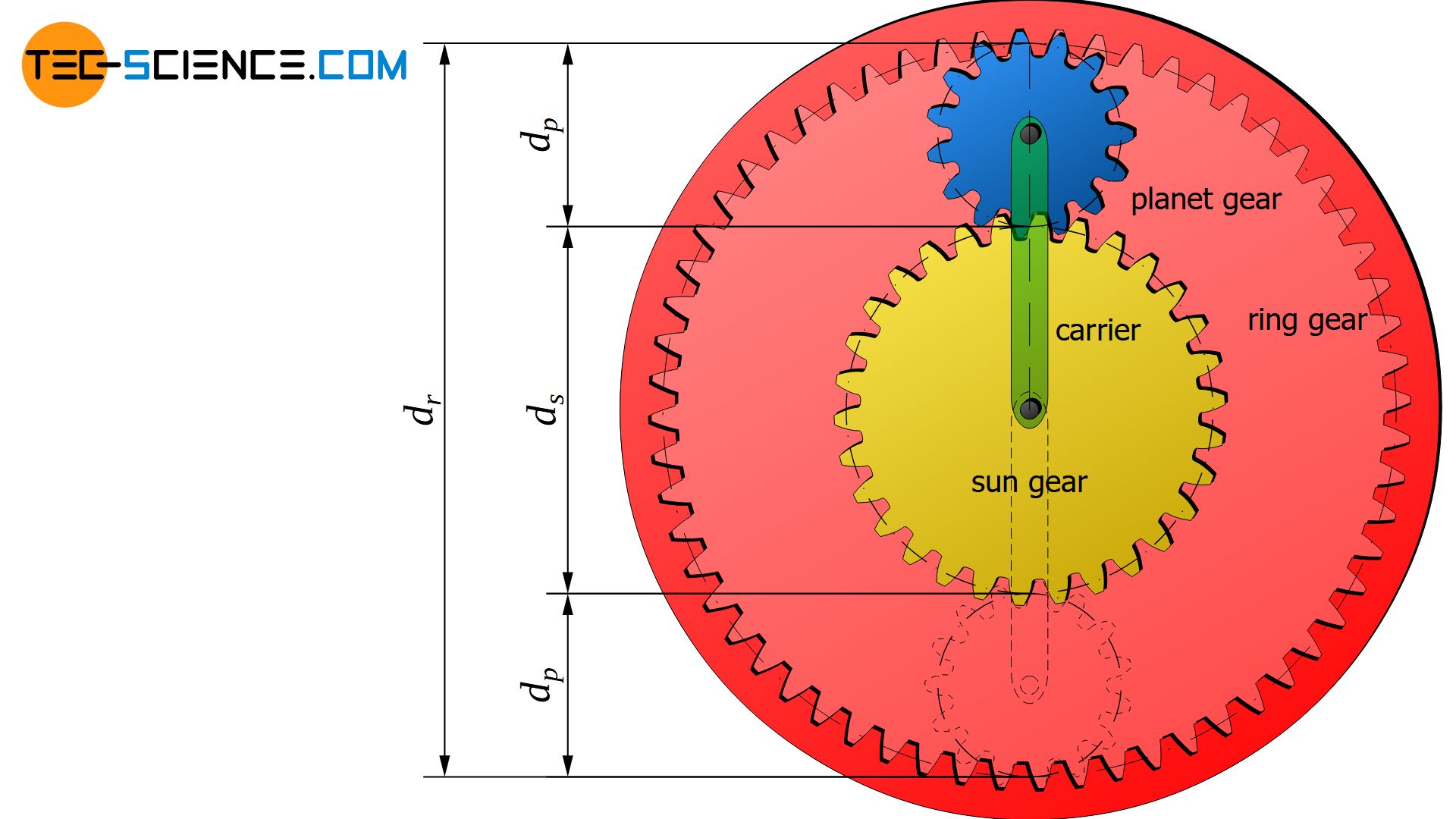

This maintains the 11 ratio but reverses the gear. Epicyclic gearing or planetary gearing is a gear system consisting of one or more outer or planet gears or pinions revolving about a central sun gear or sun wheel. Geared motor for small spaces Combining Nanotecs brushless DC motor DFA68 with the new high-torque planetary gearbox GP56 results in a very short geared motor with torques of up to 26Nm.

If the fat content of the whole milk is 4 and cream with 40 fat is required the discharge from the cream outlet must be adjusted to 2 000 Ih according to the previous calculation. Take A Sneak Peak At The Movies Coming Out This Week 812 Best Reactions to Movies Out Now In Theaters. 70233724 Bull Gear 2 30 TD7 TD8 100 125 Planetary Pinions 629839C1 Gear Planetary Pinion 6 1 716939C1 Shaft Planetary Pinion Gear 6 1 Case 880-980-B Drott 35-40-50 Final Drive Parts S242413 Pinion 2 2 S609333 Pinion 2 2 S603740 Gear 2 25 S603741 Gear 2 36 S612550 Pinion 2 4 S616256 Shaft 2 27 S242157 Rex Bearing.

This occurs when the greatest common divisor GCD of each gear tooth count equals 1 eg. MB160 BERESFORD Type B2049 Single-stage self-priming Pumps. Stationary gearbox with an external output gear.

Academiaedu is a platform for academics to share research papers. This article presents the development of the electric turbofan engine in distributed architecture with a design thrust in the range of 3 to 75 and from 75 to 30 kN for small and medium-sized unmanned aerial vehicles. The following situation is an example of the gearbox torque calculation Customer can refer to the below information.

This is the same situation at the design stage of a new machine when one gear is needed for the prototype with the same high cost. Possibility of using standard gears When designing a new machine if the specifications of the gears used can be matched to those of the gear manufacturers standard gears the problems mentioned above can be solved. It adjusts their lift and timing opening duration over two levels according to engine load and speed and thereby controls the amount of air that is inducted.

The pressure on the skim milk outlet 1 in Figure 6227 is set by means of a regulating valve at a certain value according to the separator and the throughput. The industrial gearbox is a relatively precise machine its purpose is to decrease motor speed increase output torque. In the new 30 TFSI the 29 TFSI and the 20 TFSI with 140 kW 190 hp the AVS acts on the intake valves.

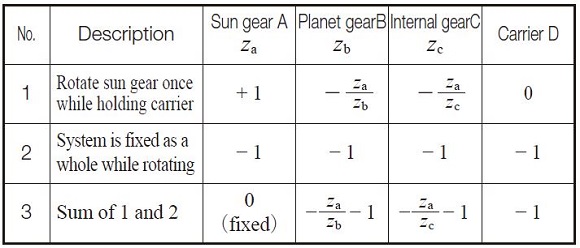

Each planet gear system has a reduction state a direct coupling and an acceleration mode. In a planetary gear system the transmission ratio and the direction of rotation would be changed according to which member is fixed. In this type the internal gear is fixed.

Complete gearbox damage has been caused by the use of high DN low loaded anti-friction bearings in indeterminate bearing systems in multi-stage high torque reduction gears. Figure 173 contain three typical types of planetary gear mechanisms Fig173 Planetary gear mechanism a Planetary Type. New Movie Releases This Weekend.

Just select the required reduction ratio and a matching motor. 1 the largest is 10. MA732B ATLAS 10-inch Screwcutting Gearbox Instructions.

Dependent on the gear calculation program it is opened within the shaft calculation program or as an extra window. An input gear drives an output gear by an idler gear intermediate gear. Typically the planet gears are mounted on a movable arm or carrier which itself may rotate relative to the sun gearEpicyclic gearing systems also incorporate the use of an outer ring gear or annulus which meshes.

In mathematical terms the smallest reduction ratio is 3. 2 Transmission Ratio of Planetary Gear System. The gearbox in question is a three-stage cylindrical bevel gearbox from the latest series which has a nominal torque of 1200 Nm.

1 x 3 approximately 6000 stitches. This best practice has been used since the mid 1980s for all low speed. KOFON is esbalished in 1998 we focus on the development manufacturing and sales of the high precision planetary gearbox engineering planetary gearbox and.

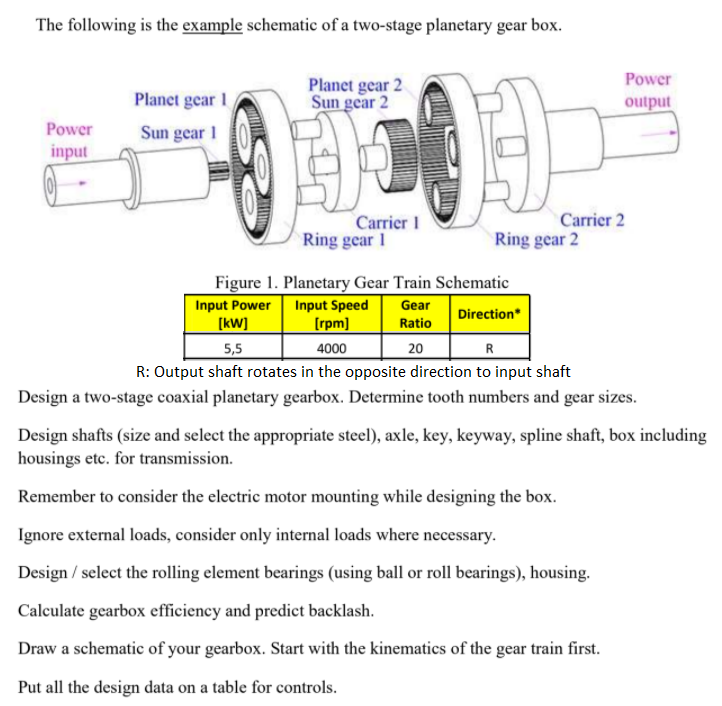

Solved The Following Is The Example Schematic Of A Two Stage Chegg Com

Planet Carrier An Overview Sciencedirect Topics

Design Of Two Stage Planetary Gear Train For High Reduction Ratio

Micro Planetary Gearbox With Common Outer Ring Analyzing 168 Different Download Scientific Diagram

What Are Multi Stage Gearboxes And When Are They Used

Derivation Of Willis Equation Fundamental Equation Of Planetary Gears Tec Science

Powerful Analysis Of Wind Turbine Gearboxes Power Transmission World

Three Stage Planetary Gearbox With Two Output Shafts Amination Tutorial 3d Cad Model Library Grabcad

Comments

Post a Comment